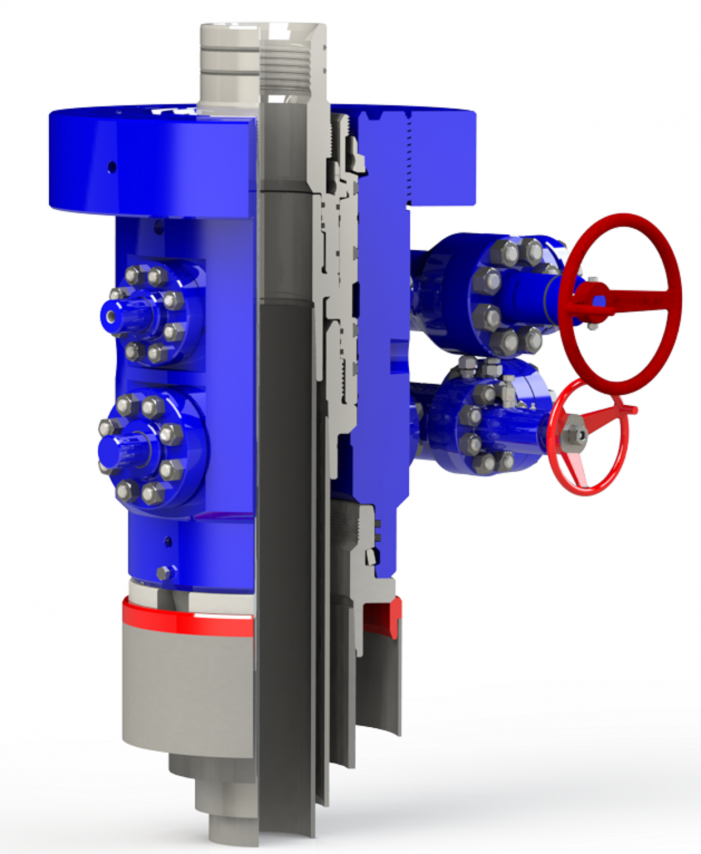

Industry’s First Snap-On Mandrel

Utilizing the surface casing mandrel from Downing, the fully assembled wellhead is installed under the rig floor onto the neck of the mandrel using our propriety latching system, resulting in a safer and faster installation. In addition, when used with offline cementing, the wellhead can be installed after cementing is complete.

Lower Cost

- Ability to install pre-assembled casing head from surface, eliminating time in the cellar. Up to 7.5 fewer hours.

- Eliminates time waiting on cement

Simple

- Install the wellhead after offline cementing is complete

- No welding

- No pup joints

- No need to go through rig floor

Safer

- No welding or torch cuts, eliminating issues with faulty welds

- The lowest red-zone personnel exposure hour solution on the market

Application:

- Drilling Efficiency

- Safety

- Offline Cementing

Key Features:

- Proprietary latch ring, eliminating the need for lock screws

- Pre-assembled casing heads landed under the rig floor

Interested in learning more about surface casing mandrels from Downing?

Email us at sales@downingusa.com

Or Call Us Now: (405) 248-9501