24/7 Continuous Pumping With Freedom Series

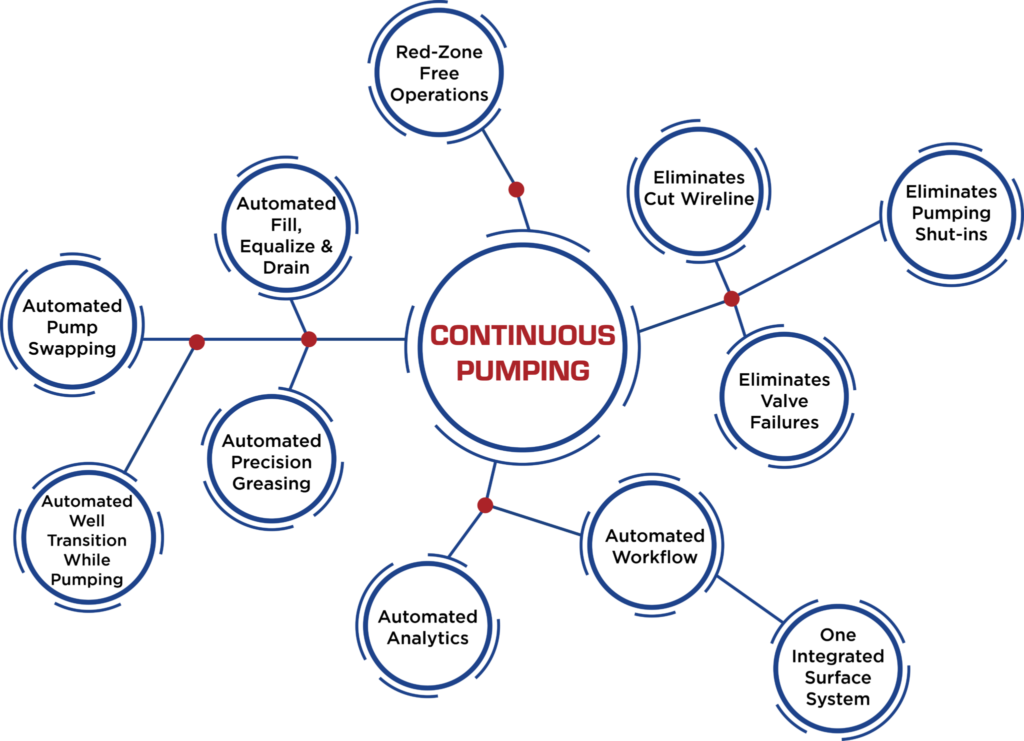

The Freedom Series Completion System eliminates the issues that prevent continuous pumping 24 hours per day, every day.

Goodbye Transition Time

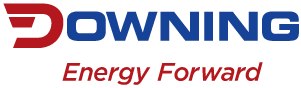

The Freedom Series Completion System integrates and automates the entire surface system into one. From automated fill, equalize, and drain to automated pump swapping, the Freedom Series Completion System enables pumping 24/7. With a simple, single click, the system transitions the zipper valves from one well to the other, opening the second well and subsequently shutting-in the first well, all while pumping. The transition is instantaneous and the total time between stages is less than 30 seconds. All data analytics are automated giving you easy access to the information. Whether a zipper frac or simulfrac, the Freedom Series Completion System simplifies your operation.

Simulfrac – Simplified Ops & Continuous Pumping

Watch as the Freedom Series Completion System transitions from 2-wells to 2-wells, actuating 11 valves and initiating greasing on each valve, all in less than 40 seconds while still pumping.

The Prize

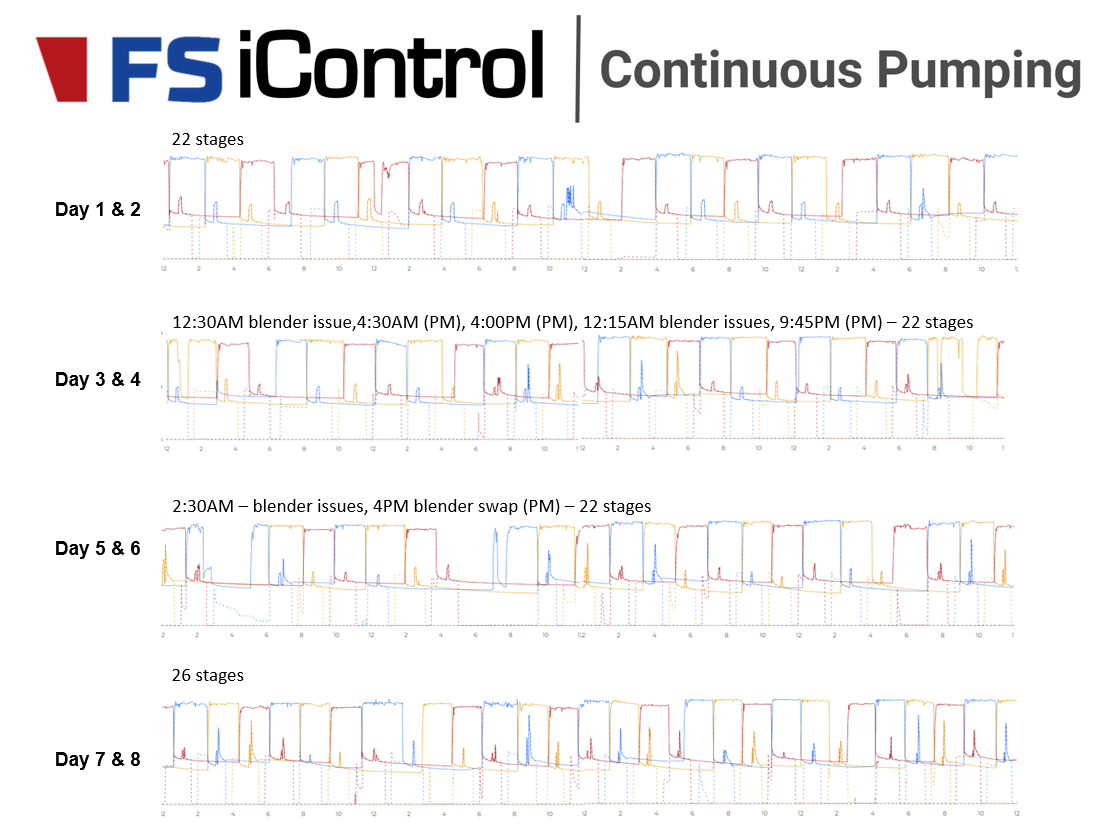

The benefits of the Freedom Series Completion System accrue to both the operator and the pumper. For the operator, lower cost frac operations and bringing on production faster. For the pumper, up to a 50% increase in pump utilization translating into higher returns on capital deployed. To illustrate, assume a pumper fleet, with 32 crews, averages 16 hrs pumping per day, moving this to 23.5 hrs/day adds the equivalent of 13 crews without additional capital spend, representing a step change in completion efficiency analogous to the efficiency gains seen in drilling 20+ years ago when the industry transitioned from tricones to PDC bits.

Why Choose Automation?

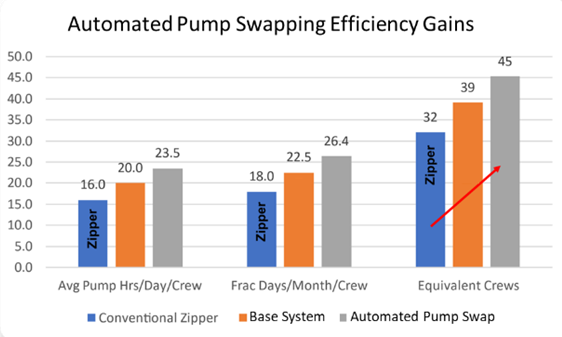

Traditional frac operations combine human driven processes with multiple surface system vendors on a site. When an error occurs resulting in NPT, the limited, non-granular data available is not enough to identify the true root cause, resulting in finger pointing among the multiple vendors. The typical resolution is more processes, another checklist, more people, and/or more training. When an issue occurs with the Freedom Series Completion System, the data available enables Downing to pinpoint the issue and engineer it out, eliminating the issue and permanently improving the system. This NPT becomes a one-time issue versus an issue occurring repeatedly with human driven workflows.

Common Objections to Implementing Freedom Series

- “We are really efficient” – “really efficient” versus today’s standard. Freedom Series Completion System is setting a new standard.

- “You must be down for a day repairing pumps after continually pumping” – With the Freedom Series Completion System, we cluster frac (continuously pumping multiple stages, doing a quick maintenance cycle, and repeating).

- “My pumper can’t keep up with our current pumping plans” – Freedom Series Completion System inherently speeds up the process, raising the bar for everyone on pad. This has been demonstrated pad after pad after pad through 80000+ stages.

- “We already pump 22 hrs per day” – this typically refers to a one-time event and not a consistent pattern over an entire job, as will be the case with the Freedom Series Completion System.

- “I have other issues that I need to fix before we take on the automated surface system” – Freedom Series Completion System simplifies the process, eliminating many of the issues operators are trying to eliminate with additional process. Simplify your frac operations today, freeing up your personnel to focus on other issues.

- “No one can continually pump in the Haynesville” – Downing broke this barrier in early 2023, pumping 35 hrs straight and multiple 24 hr pumping days.

The Ultimate Automated Completion System

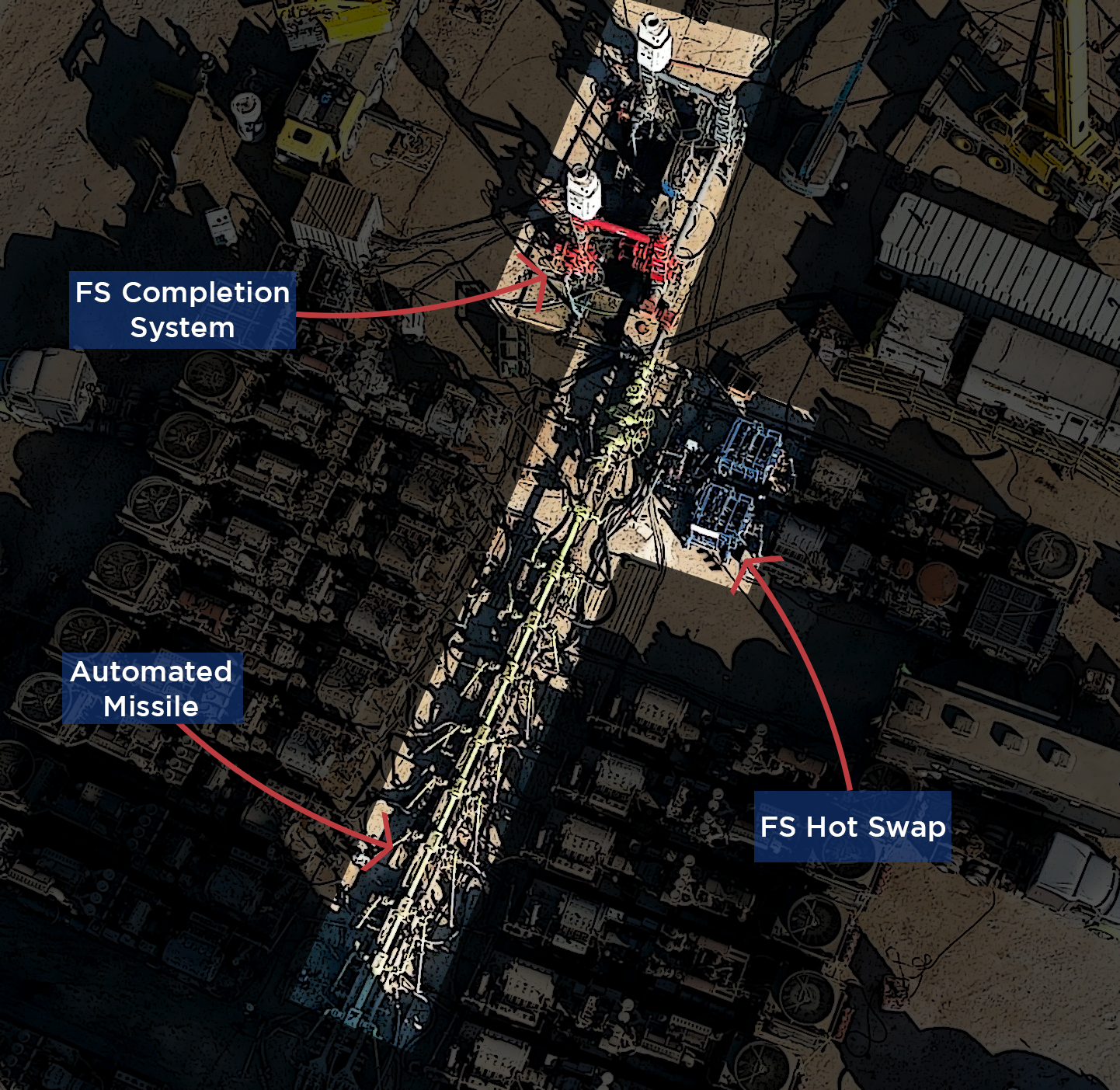

Automated Lubricator

- Automates the latch, pre-fill and equalization of the lubricator.

- Includes patented automated vent sub technology and RFID technology.

Automated Missile

- Enables isolation of individual pumps during pumping without personnel in the red zone.

- Reduces time required to swap a pump by rapidly bleeding pressure down.

- Accurately and quickly equalizes missile with the well.

- In conjunction with FS Hot Swap, allows pumps to be replaced and brought back online during frac operations without personnel in the red zone.

- Automated latch – enables red zone free lubricator attachment.

- Automated valve – allows rapid equalization, eliminates cut wireline, and reduces valve maintenance.

- Automates the process of replacing pumps without going into the red zone during pumping operations.

- Controls all gate valves (whether Downing valves or third party)

- Automated greasing of all valves on every actuation

- Enables continuous pumping operations through automated valve transition while pumping.

- New greasing algorithms ensure every valve receives the proper amount of grease, reducing grease consumption by 90% and significantly reducing valve failures and repairs.

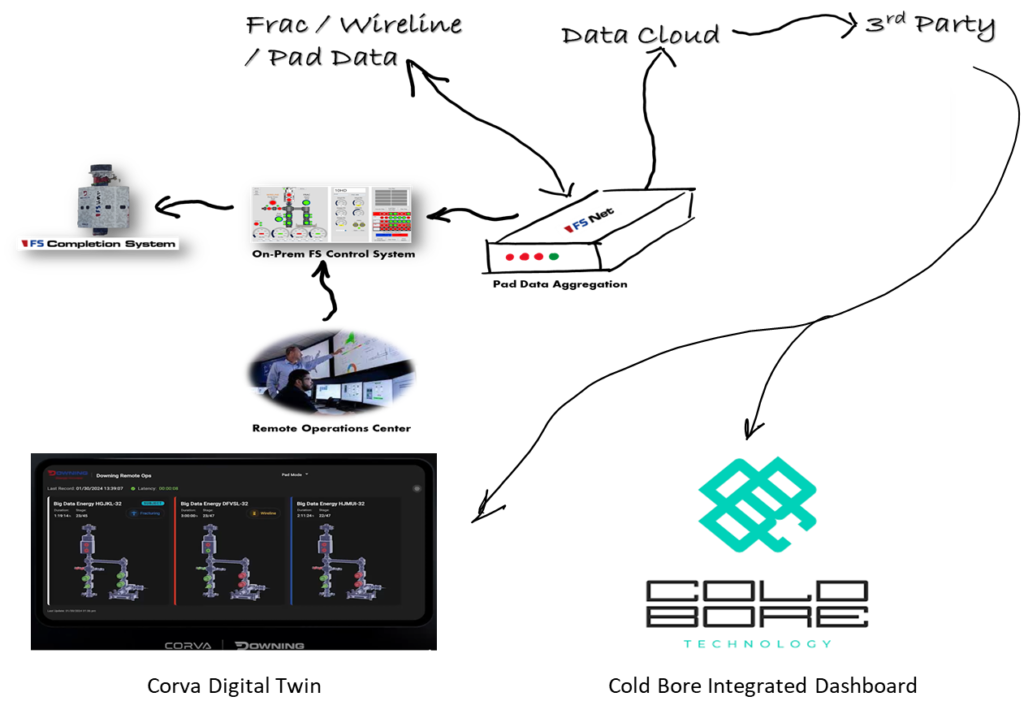

Freedom Series: Built for Remote Operations

- Low latency, live data feed.

- Integrated Cold Bore dashboard, standard.

- Integrated digital twin by Corva, standard.

- Integrated system with single click workflow giving the operator both control and data in one system.

- Data interlocks with both wireline and frac pumps significantly reduce chance of error.

- Whether in the frac van or thousands of miles away, the system is operated as if you were next to the well.

- FS Net enables the aggregation and integration of pad data.

- Stream your data onsite, to the cloud, or to a third party.

The Benefits

Delivering freedom from…

Unplanned Costs

Downtime

Red Zone Risks