Downing Speed Head Systems are designed and manufactured in-house to bring you maximum efficiencies, minimal downtime and improved safety. Our proprietary systems eliminate wait time for cement setting and casing cutting processes.

Speed Head Systems

Downing Speed Head Systems are designed and manufactured in-house to bring you maximum efficiencies, minimal downtime and improved safety. Our proprietary systems eliminate wait time for cement setting and casing cutting processes.

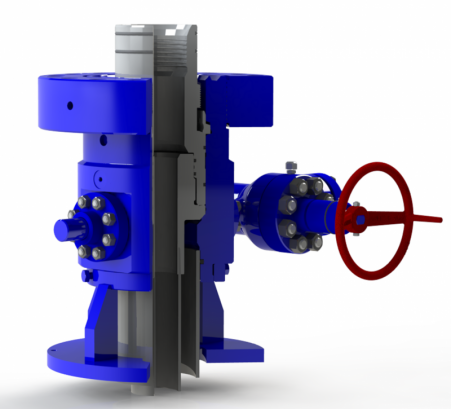

- Designed for 2-string applications

- Install fluted mandrel hanger & packoff seal through BOP stack

- Variety of configurations available

- Conventional wellhead cost with time-saving benefits of mandrel hangers

- Internal latch eliminates lock screw leak paths

- Optional quick connect

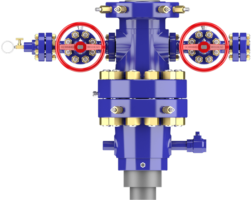

- Variety of configurations available

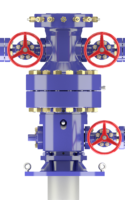

- For 2 Casing String applications and multi-well pads with batch drilling

- DSH-2S: Casing slip only version available

- Designed for 2-string applications

- Install fluted mandrel hanger & packoff seal through BOP stack

- Variety of configurations available

- Conventional wellhead cost with time-saving benefits of mandrel hangers

- Internal latch eliminates lock screw leak paths

- Optional quick connect

- Variety of configurations available

- For 2 Casing String applications and multi-well pads with batch drilling

Why Choose a Downing Speed-Head System?

U.S. Manufacturing

In-house Engineering

API 6A Certified