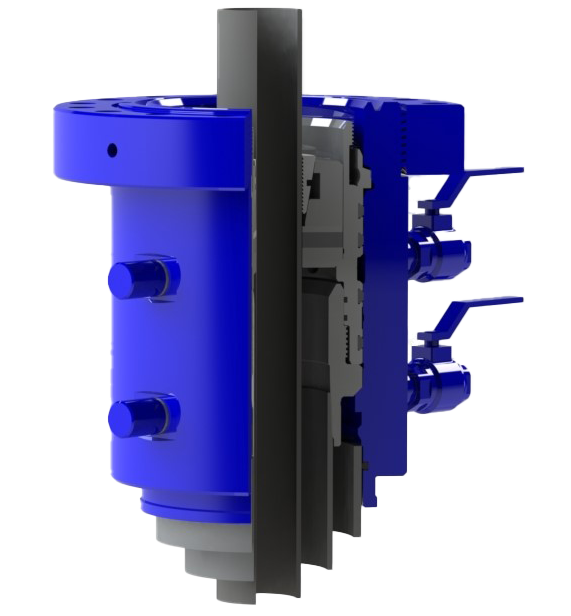

Internal Latch Multi-Bowl Wellhead System

5K Application-Specific MB-45

Improve Safety

- Lock screw leak paths eliminated

- Significantly less redzone exposure

Minimize Downtime & Costs

- Install intermediate production casing without removing BOP

- Less time waiting on cement and casing cutting

- Realized total time savings exceeding 24 hours per well vs conventional wellhead systems

Improve Efficiencies

- Enhanced cementing operations

- Run, land and install housing through the rig floor

MB-4 VS MB-45

Features

MB-4

MB-45

Surface Casing Mandrel

Surface Casing Mandrel

Surface Casing Mandrel

Slip-on Weld (SOW)

Slip-on Weld (SOW)

Slip-on Weld (SOW)

Pre-welded Pup Joint

Pre-welded Pup Joint

Pre-welded Pup Joint

10k System Available

10k System Available

10k System Available

5k System Available

5k System Available

5k System Available

Side Studded Outlets

Side Studded Outlets

Side Studded Outlets

Line Pipe Outlets

Line Pipe Outlets

Line Pipe Outlets

Intermediate Production Casing Mandrel / Seal Support

Intermediate Production Casing Mandrel / Seal Support

Intermediate Production Casing Mandrel / Seal Support

Production Casing Mandrel / Pack Off

Production Casing Mandrel / Pack Off

Production Casing Mandrel / Pack Off

C-22 Slips for Production Casing

C-22 Slips for Production Casing

C-22 Slips for Production Casing

C-21 Slips and Pack Off

C-21 Slips and Pack Off

C-21 Slips and Pack Off

Threaded Flange on Casing Head

Threaded Flange on Casing Head

Threaded Flange on Casing Head

Internal Latch

Internal Latch

Internal Latch

Quick Connect Compatible

Quick Connect Compatible

Quick Connect Compatible

Install System Through Rotary Table

Install System Through Rotary Table

Install System Through Rotary Table

Application:

- 3+ Casing Strings

- Multi & Single Well Pads

Key Features:

- Unitized design reduces height to 26 3/8″ vs MB-4

- No lock screws below tubing head

- Mandrels available in all common intermediate production casing sizes

- Threaded on 13-5/8” 5K API OEC flanges (optional with Quick Connect)

- Nested 11” bowl accommodates C-22 style slip hanger

- Variety of configurations available