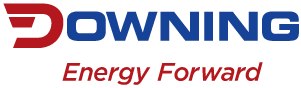

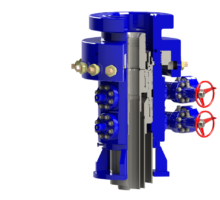

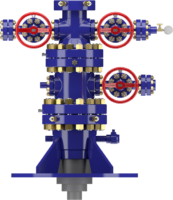

Wellhead Systems

Downing manufactures wellhead systems and application-specific production trees that include a variety of features and 24/7 support. We’ll develop the optimal wellhead solution for your application, considering:

- Operating Conditions

- Casing Strings

- Geography

- Rig Type

- Pad & Cellar Designs

- Installation Variables

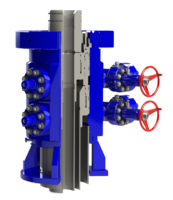

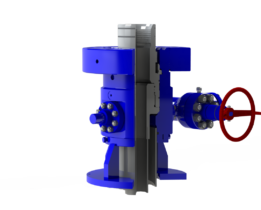

- Casing Heads & Spools

- Tubing Heads

- Casing & Tubing Hangers Adapter Flanges

- Bottom Hole Test Adapters

- Wedge Expanding Gate Valves

- Slab Gate Valve

- Chokes

- Crosses & Tees

- Seals

- ESP Compatible

- Equipment installation

- Preventative maintenance and lubrication

- Field survey & well identification

- Well completion & de-completion

- Torque & testing services

- On-site equipment repairs

Why Choose a Wellhead System from Downing?

At Downing, we have the ability and flexibility to design, engineer and build wellhead systems at our US manufacturing facility located in Oklahoma City. Our location and in-house engineering mean that we consistently outperform our competitors on lead time. This means you get unrivaled responsiveness, reliability and faster production.

US Manufacturing

In-house Engineering

API 6A Certified