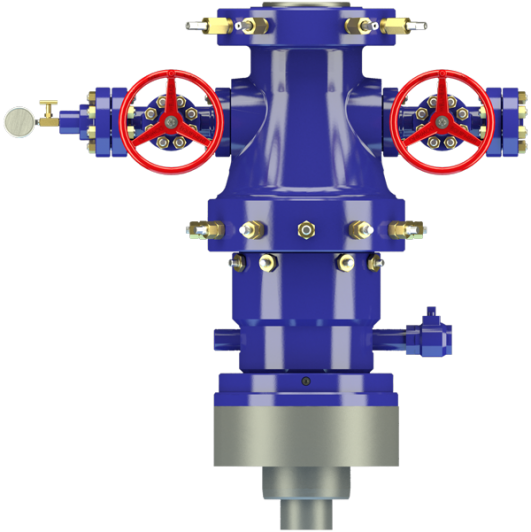

Significantly reduce installation time with the Downing Quick Connect Wellhead System. The DQC-2 enables you to quickly detach and re-attach the BOP stack, eliminating the need for cutting casing, welding and waiting for cement to set. By installing the casing head through the rig floor and riser pipe, the DQC-2 substantially improves speed in batch drilling applications and significantly reduces rig time on multi-well pads.

DQC-2 Wellhead System includes:

- Quick Connect BOP Adapter

- Quick Disconnect Capping Flanges

- Quick Connect for Tubing Head

Key Features:

- For use with 2-string applications

- 11” 5K API OEC Quick Connection

- Premium or API threaded mandrel hangers

- Ideal for pad well drilling or infield drilling using the same rig

- Optional diverter riser system available with cement return capabilities

- Landing ring for conductor

- Casing head can be landed through 20” or larger diverter riser

- Drifts a 17.5” Rotary Table

- Mandrel hangers and packoff seals

- Back pressure valve configuration available

Why Choose the DQC-2 Wellhead System?

Increase Flexibility

- Option to run and land surface casing with slip on weld sputter casing

- Run surface casing through diverter/riser pipe while casing is suspended

Improve Safety

- Reduced exposure to safety hazards

- Employees spend less time under rig floor

- BPV prep in production mandrel provides barrier while tubing head is installed

Minimize Downtime

- Reduced rig time

- QC optimized for batch drilling

- Mandrel hangers virtually eliminate casing cutting time and the need to wait on cement to set

Improve Efficiencies

- Run surface casing & head through the rotary table

- Quick connector eliminates need for torque & test crew to make up BOP or tubing head connection

- Run, land, and hang production casing through rig floor

- Take returns through the BOP stack