Re-prints of industry-wide publications featuring Downing products and solutions. Gain in-depth knowledge about our offerings from publications like World Oil, Simmons Energy, and more.

WORLD OIL | MAY 2023

Tim Marvel, Austin Johnson, Phillip Douget, Michael Mast, John Dyer, Jordan Kuehn, Brian Wiesner

By identifying the numerous barriers obstructing 24/7 reservoir fracturing, a newly developed system utilizes advanced processes and technologies. The system has led to gains in operational efficiency, consistency and safety, enabling operators to fracture a reservoir more hours/day compared to standard procedures and techniques.

PETROLEUM PRODUCTS AND SOLUTIONS | MAY 2023

Freedom Series Completion System is for continuous pumping 24 hours a day, seven days a week.

WELL SERVICING MAGAZINE | JUNE 2022

By Tim Marvel

Downing, a leading technology provider, has developed an automated system that methodically eliminates the time between plug-and-perf stages with the goal of fracturing the reservoir 24 hours a day, seven days a week.

THE AMERICAN OIL & GAS REPORTER | MARCH 2022

By Colter Cookson

AOGR added Downing’s Freedom Series Completion System to its report on advanced completion equipment, highlighting the faster completions it is delivering to Downing’s customers. Downing’s objective of facilitating 24/7 continuous pumping is emphasized with a preview of a new product developed to address pump maintenance down time.

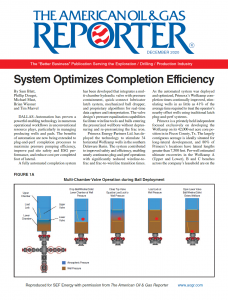

THE AMERICAN OIL & GAS REPORTER | DECEMBER 2020

SYSTEM OPTIMIZES COMPLETION EFFICIENCY

By Sam Blatt, Phillip Douget, & Michael Mast | Primexx

Brian Wiesner | Downing

Tim Marvel | SEF Energy

AOGR highlights the benefits of Downing’s Freedom Series Completion System on Primexx’s Delaware Basin completions. At the time the case history was written, 19 horizontal wells had been completed with a 50% improvement in the rate of completion. Find out how Primexx has deployed the Freedom Series to greatly enhance their operations.

HART ENERGY | SEPTEMBER 2020

AUTOMATING WELL COMPLETIONS

Tim Marvel and Austin Johnson | Downing USA

A new system reduces stage-to-stage transition time from 45 minutes to less than 3 minutes while ensuring the safety of personnel.

TPH EQUITY RESEARCH | DECEMBER 2019

SECTOR UPDATE: DOWNING DRIVING COMPLETION EFFICIENCIES ON THE WELLSITE

George O’Leary, Byron Pope, Taylor Zurcher & Dhruv Kharbanda | TPH & Co.

Downing is an oilfield equipment and products manufacturer acutely focused on enhancing efficiencies for its customers in the oil patch, primarily via their new Freedom Series (“FS”) completion system. We went out to visit the team in their OKC headquarters and to take a look under the hood at the new completion solutions offering. We enumerate a number of incremental benefits that the FS system offers in our full report (available for download), but at a high level, we believe that increasing hours pumped / frac stages per day and reducing NPT are the two primary reasons oil & gas players should consider the system as a valuable weapon in their well completions arsenal.

WORLD OIL | NOVEMBER 2019

AUTOMATION RESULTS IN SIGNIFICANT COMPLETION EFFICIENCY GAINS IN DELAWARE BASIN

Austin Johnson & Kim McKimmey, Downing

As West Texas operator Primexx Energy Partners has pursued an aggressive program to delineate and develop its Delaware basin acreage in Reeves County, the company has leveraged new technology to increase the efficiency of completion and stimulation operations and achieve significant cost-savings. Downing’s new Freedom Series Completion System (FSCS) has been a key factor in helping Primexx significantly reduce the number of days on location by increasing stages per day by 20% to 60%, resulting in major cost reductions and time savings.

![WO1119 Johnson—ShaleTech Report Practices[1]_Page_1 World oil Shale Tech Report page](https://downingusa.com/wp-content/uploads/WO1119-Johnson—ShaleTech-Report-Practices1_Page_1-224x300.jpg)

SIMMONS ENERGY | NOVEMBER 2019

LETTER FROM THE ROAD – RECAP FROM OKLAHOMA

John Daniel, John Watson & Dylan Glosser, Simmons Energy

Downing’s FS Completion System was recently featured in Simmons Energy’s Oklahoma recap on new technologies being developed in the Sooner state. Simmons believes the FS Completion System is likely to be a disruptive force in the completions industry, contributing to rising frac efficiencies and improving stages completed per day. Read the report highlighting the FS Completion System.